Understanding PEX Shut Off Valves for Sink Plumbing

PEX (cross-linked polyethylene) plumbing has gained significant popularity in recent years due to its flexibility, durability, and ease of installation. A critical component of any plumbing system, including those using PEX, is the shut-off valve. These valves allow for the isolation of water supply to specific fixtures, such as sinks, for maintenance, repair, or replacement without disrupting the water supply to the entire building. This article will provide a comprehensive understanding of PEX shut-off valves used in sink plumbing systems.

Shut-off valves are essential safety and practicality features in any plumbing system. They provide a localized control point for water flow, preventing potential water damage and inconvenience. Without shut-off valves, even minor plumbing repairs would necessitate the complete shutdown of the building's water supply, affecting all occupants and interrupting other essential services. Additionally, the ability to isolate specific fixtures allows for targeted troubleshooting and prevents unnecessary disruption during maintenance or emergencies.

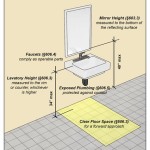

Specifically, PEX shut-off valves designed for sink applications are typically compact and designed to be installed beneath the sink, connecting the incoming water supply lines to the faucet connections. They are available in various configurations and connection types, catering to different plumbing setups and installation preferences. The selection of the correct valve is crucial for ensuring a reliable and leak-free connection.

Key Considerations When Choosing a PEX Shut Off Valve for a Sink

Selecting the appropriate PEX shut-off valve for a sink involves careful consideration of several key factors. These include the connection type, valve type, material, and size, all of which contribute to the overall performance, durability, and ease of installation of the valve.

Connection Type: PEX connections come in various forms, including crimp ring, push-fit, and expansion fittings. Crimp ring connections require a crimping tool and copper or stainless steel rings to secure the PEX tubing to the valve. Push-fit connections offer a tool-free installation, allowing the PEX tubing to be simply pushed into the valve until it locks in place. Expansion fittings utilize an expansion tool to enlarge the PEX tubing before inserting it onto the valve, creating a secure and leak-proof connection as the tubing contracts. The choice of connection type often depends on the installer's preference, existing tools, and the specific requirements of the plumbing system.

Valve Type: Common types of shut-off valves include ball valves, quarter-turn valves, and multi-turn valves. Ball valves feature a ball with a hole drilled through it. When the handle is turned, the hole aligns with the water flow, allowing water to pass through. A quarter-turn valve is very similar in design to a ball valve, often using a ball valve mechanism. Multi-turn valves require several rotations of the handle to fully open or close the valve. Ball valves and quarter-turn valves are generally preferred for their quick and easy operation, allowing for a rapid shut-off of the water supply. Multi-turn valves offer finer control over water flow but are slower to operate.

Material: PEX shut-off valves are commonly made of brass, plastic (such as CPVC or polypropylene), or a combination of both. Brass valves are known for their durability and corrosion resistance, making them a reliable choice for potable water systems. Plastic valves are typically less expensive and are resistant to corrosion, but may not be as durable as brass valves. The choice of material depends on budget considerations, water quality, and the desired lifespan of the valve.

Size: PEX shut-off valves come in various sizes to match the diameter of the PEX tubing being used. The most common sizes for sink plumbing are 1/2 inch and 3/8 inch. It is essential to select a valve that matches the size of the PEX tubing to ensure a proper and leak-free connection. Using an incorrectly sized valve can lead to leaks, reduced water flow, and potential damage to the plumbing system.

Installation Procedures for PEX Shut Off Valves Under Sinks

Proper installation of PEX shut-off valves is crucial for ensuring a reliable and leak-free plumbing system. While specific steps may vary slightly depending on the type of valve and connection type, the following general procedure outlines the typical installation process.

Preparation: Before beginning the installation, the main water supply to the building must be turned off to prevent water leakage. Gather all necessary tools and materials, including the PEX shut-off valve, PEX tubing cutter, crimping tool (if using crimp ring connections), push-fit tool (if using push-fit connections), expansion tool (if using expansion connections), PEX tubing, and any necessary fittings or adapters. It is also advisable to have a bucket and towels on hand to catch any residual water in the pipes.

Removing the Old Valve (if applicable): If replacing an existing valve, carefully disconnect the old valve from the PEX tubing. Use a PEX tubing cutter to make a clean and square cut of the PEX tubing as close to the old valve as possible. Ensure that the cut is free of burrs or imperfections, as these can compromise the connection with the new valve. Dispose of the old valve properly.

Preparing the PEX Tubing: Inspect the PEX tubing for any damage or deformation. If necessary, cut the tubing to the appropriate length using a PEX tubing cutter. Ensure that the cut is clean and square. For crimp ring connections, slide a crimp ring onto the PEX tubing before inserting it onto the valve. For push-fit connections, simply push the PEX tubing into the valve until it locks in place. For expansion connections, use an expansion tool to expand the PEX tubing before inserting it onto the valve.

Connecting the Valve: Carefully insert the PEX tubing onto the valve, ensuring that it is fully seated. For crimp ring connections, position the crimp ring over the barb of the valve and use a crimping tool to crimp the ring securely. Ensure that the crimp is properly formed and evenly distributed around the ring. For push-fit connections, verify that the PEX tubing is fully inserted and locked in place. For expansion connections, allow the expanded PEX tubing to contract around the valve, creating a tight and secure connection.

Testing for Leaks: Once the valve is connected to the PEX tubing, slowly turn on the main water supply to the building. Carefully inspect the connections for any leaks. If leaks are present, turn off the water supply and tighten the connections as needed. For crimp ring connections, double-check the crimp and re-crimp if necessary. For push-fit connections, ensure that the PEX tubing is fully inserted and locked in place. For expansion connections, check that the expansion joint is properly formed and sealed.

Securing the Valve: Once the connections are leak-free, secure the valve in place using appropriate mounting brackets or straps. This will help to prevent strain on the connections and ensure the long-term stability of the valve. Consider the positioning of the valve for future accessibility to allow for easy shut-off if needed. Confirm the area surrounding the shut-off valve is easily accessible for maintenance or replacements.

Troubleshooting Common Issues with PEX Shut Off Valves

Like any plumbing component, PEX shut-off valves can experience issues over time. Common problems include leaks, difficulty turning the valve handle, and reduced water flow. Understanding the possible causes and solutions for these issues can help maintain the plumbing system's integrity.

Leaks: Leaks are a common issue with shut-off valves, often occurring at the connections or around the valve stem. Leaks at the connections can be caused by improper installation, loose connections, or damaged PEX tubing. To address leaks at the connections, first, ensure that the connections are properly tightened. If the leak persists, inspect the PEX tubing for any damage or deformation. Damaged tubing should be replaced. If using crimp ring connections, check the crimp for proper formation and re-crimp if necessary. If the leak is around the valve stem, the valve stem packing may need to be tightened or replaced. Replacing the entire valve may be necessary in extreme cases.

Difficulty Turning the Valve Handle: A stiff or difficult-to-turn valve handle can be caused by mineral buildup, corrosion, or a damaged valve mechanism. To address this issue, first, try lubricating the valve stem with a silicone-based lubricant. This can help to loosen up any mineral buildup or corrosion. If the handle remains difficult to turn, the valve may need to be disassembled and cleaned. However, disassembly can be complex and may require specialized tools. In some cases, it may be more practical to replace the entire valve.

Reduced Water Flow: Reduced water flow through the shut-off valve can be caused by debris buildup, corrosion, or a partially closed valve. To address this issue, first, ensure that the valve is fully open. If the water flow remains reduced, the valve may need to be disassembled and cleaned. Debris can accumulate inside the valve, restricting water flow. Cleaning the valve can remove any obstructions and restore optimal flow. In severe cases of corrosion or damage, replacing the entire valve may be necessary.

In summary, understanding the different types of PEX shut-off valves available, properly installing them, and troubleshooting common issues are crucial for maintaining a reliable and efficient plumbing system. Properly selected, installed, and maintained PEX shut-off valves will ensure a long-lasting and trouble-free plumbing system.

Wall Shut Off For Pex Distribution Internachi Forum

Keeney 1 2 In Comp Pex X 3 8 O D Quarter Turn No Crimp Angle Valve Pp2886ez The Home

Flowtite 4all And Pushon Pex For New Pipe Accor Technology

Keeney 1 2 In Comp Pex X 3 8 O D Quarter Turn No Crimp Angle Valve Pp2886ez The Home

How To Install A Pex Supply Stop Valve Youtube

Sharkbite 3 8 In Pex X Od Compression Brass Quarter Turn Stop Straight Valve 25898lf At Com

Brass Expansion Angle Stop Valve Sharkbite

Diy Beginner Guide For Choosing The Right Shutoff Valve Sink Toilet Youtube

Pex Piping With Quarter Turn Shutoff Valves And Brass Fittings

Sharkbite 3 8 In Pex X Od Compression Brass Quarter Turn Stop Angle Valve 25897lf At Com