Kitchen Countertop With Sink Built In: A Comprehensive Guide

The integration of a sink directly into a kitchen countertop, creating a seamless and unified surface, represents a significant design choice with implications for functionality, aesthetics, and overall kitchen workflow. This approach, often referred to as an integrated sink or a molded sink, offers a contemporary look and can enhance the hygienic properties of the countertop. The following article provides a detailed exploration of kitchen countertops with built-in sinks, encompassing material options, design considerations, installation processes, and maintenance practices.

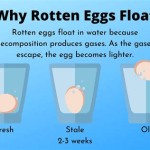

Integrated sinks eliminate the traditional lip or seam where a drop-in or undermount sink meets the countertop material. This lack of a seam minimizes the potential for water and debris accumulation, reducing the risk of mold and bacterial growth. Furthermore, the smooth transition between the countertop and the sink bowl visually expands the perceived workspace and contributes to a more streamlined and modern kitchen aesthetic. However, the fabrication and installation of integrated sinks often require specialized skills and equipment, potentially increasing the initial cost compared to conventional sink installations.

The decision to opt for a kitchen countertop with a built-in sink hinges on a multitude of factors, including budget, design preferences, anticipated usage, and the long-term maintenance requirements of the chosen material. Understanding the nuances of each aspect is crucial for making an informed decision that aligns with individual needs and lifestyle.

Material Selection for Integrated Kitchen Countertops

The choice of material for a kitchen countertop with a built-in sink is paramount, as it dictates the countertop's durability, aesthetic appeal, and susceptibility to staining, scratching, and heat damage. Several materials are suitable for creating integrated sinks, each possessing unique characteristics that influence their suitability for specific applications.

Solid surface materials, such as Corian, Hi-Macs, and Avonite, are popular choices for integrated sinks. These materials are acrylic-based or polyester-based composites that can be seamlessly molded to create a continuous surface. They offer excellent stain resistance, are non-porous, and can be repaired relatively easily if damaged. Furthermore, solid surface materials are available in a wide array of colors and patterns, providing ample design flexibility. The ability to sand out scratches and minor damage is a significant advantage, extending the lifespan of the countertop and maintaining its pristine appearance.

Quartz composite, engineered from ground quartz crystals bound together with resin, offers exceptional durability and scratch resistance. While quartz countertops with integrated sinks are less common than solid surface options, they are becoming increasingly prevalent. The non-porous nature of quartz makes it highly resistant to staining and bacterial growth. However, the fabrication of integrated sinks from quartz composite can be more complex, potentially increasing the cost. Color options for quartz are also typically more limited compared to solid surface materials.

Natural stone materials, such as granite and marble, can theoretically be used to create integrated sinks. However, this approach is rarely pursued due to the inherent challenges associated with fabricating such complex shapes from natural stone and the increased risk of cracking or chipping. Natural stone is also porous and requires regular sealing to prevent staining. Furthermore, the cost of fabricating and installing an integrated sink from natural stone is significantly higher than that of other materials.

Concrete is another option for crafting custom countertops with integrated sinks. Concrete countertops offer a unique, industrial aesthetic and can be tinted to achieve a wide range of colors. However, concrete is porous and requires sealing to resist staining and water damage. The weight of concrete countertops also necessitates robust cabinet support. The fabrication process involves creating a mold and casting the concrete, which can be labor-intensive and require specialized expertise.

Design Considerations for Integrated Sinks

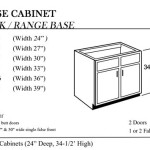

Beyond material selection, careful consideration must be given to the design of the integrated sink itself. Factors such as sink size, bowl depth, number of bowls, and drain placement significantly impact the functionality and usability of the kitchen countertop. The design should complement the overall style of the kitchen and cater to the specific needs of the user.

The size of the sink should be proportional to the countertop area and the overall dimensions of the kitchen. A larger sink may be desirable for households that frequently cook or entertain, while a smaller sink may suffice for individuals or couples with limited countertop space. The depth of the sink bowl also plays a crucial role in determining its capacity to accommodate large pots and pans. A deeper bowl offers greater versatility but may also require more bending, which can be uncomfortable for some users.

The decision to incorporate a single-bowl or double-bowl sink depends on individual preferences and usage patterns. A single-bowl sink provides ample space for washing larger items, while a double-bowl sink allows for simultaneous washing and rinsing. Some integrated sink designs incorporate a small, shallow basin for food preparation or disposal.

Drain placement is another important design consideration. A center drain is the most common configuration, but an offset drain can provide more usable space within the sink bowl. The position of the drain should also be considered in relation to the plumbing connections and the configuration of the under-sink cabinet.

The style of the sink bowl rim, or the transition between the sink and the countertop, can significantly influence the aesthetic appeal of the integrated sink. A sharp, angular rim creates a more modern look, while a rounded rim offers a softer, more traditional feel. The rim can also be designed to be flush with the countertop, providing a completely seamless transition.

Installation and Maintenance of Integrated Countertops

The installation of a kitchen countertop with a built-in sink is a complex process that typically requires professional expertise. Precise measurements, accurate cutting, and meticulous joining are essential to ensure a seamless and watertight installation. Improper installation can lead to leaks, structural weaknesses, and aesthetic imperfections.

The installation process begins with careful measurement and templating of the countertop area. A custom template is created to ensure a precise fit. The countertop material is then cut to size and the sink bowl is integrated using specialized tools and techniques. The joining process involves creating a seamless bond between the countertop and the sink, typically using adhesives or heat welding. Once the countertop is installed, the plumbing connections are made and the sink is tested for leaks.

The maintenance requirements of an integrated sink countertop vary depending on the material. Solid surface materials are relatively easy to clean and maintain. Regular wiping with a damp cloth and mild detergent is typically sufficient to remove stains and spills. Abrasive cleaners should be avoided, as they can dull the surface. Minor scratches can be buffed out with a non-abrasive cleaner or a specialized polishing compound. More significant damage may require professional repair.

Quartz composite countertops are also relatively easy to maintain. Regular cleaning with a damp cloth and mild detergent is sufficient to remove most stains and spills. Avoid using harsh chemicals or abrasive cleaners, as they can damage the surface. Quartz countertops are highly resistant to staining, but it is still advisable to wipe up spills promptly to prevent discoloration.

Natural stone countertops require more diligent maintenance. Regular sealing is essential to prevent staining and water damage. Clean spills immediately with a soft cloth and mild detergent. Avoid using acidic cleaners, as they can etch the surface. Natural stone countertops are susceptible to scratching and chipping, so it is important to handle them with care.

Concrete countertops also require regular sealing to protect against staining and water damage. Clean spills promptly with a soft cloth and mild detergent. Avoid using acidic cleaners or abrasive sponges. Waxing the concrete surface can provide an additional layer of protection and enhance its sheen.

In summary, the installation and maintenance of a kitchen countertop with a built-in sink are crucial for ensuring its longevity and functionality. Choosing the right material, carefully considering the design, and following proper installation and maintenance procedures are essential for maximizing the value and enjoyment of this integrated kitchen feature.

Kitchen Countertop With Built In Dish Drainer Board Transitional

Integrated Sinks Concrete Creations Nwa

Kitchen Design Idea Seamless Sinks Integrated Into The Countertop

One Piece Sink And Countertop Designs For Your Kitchen

Stylish Kitchen Sink Trends Amanzi Marble Granite

Sink Options For Laminate Countertops

Experience Modern Style Convenience And Efficiency Built In Kitchen Sink With Automatic Countertop Dishwasher Set For Effortless Cleaning Stainless Steel Double Bowl Made China Com

Wilsonart Hd Sink Kitchen Studio Of Naples Inc

11 Kitchen Sinks That Are Far From Normal

Pros And Cons Of Integrated Sinks Chica Dragon