Soap Dispenser Pump For Sink: A Comprehensive Guide

A soap dispenser pump integrated into a sink offers a convenient and hygienic solution for dispensing hand soap, dish soap, or lotion directly at the point of use. These dispensers eliminate the need for separate soap bottles cluttering countertops, contributing to a cleaner and more organized kitchen or bathroom environment. The design and functionality of these pumps have evolved significantly, incorporating various materials, mechanisms, and aesthetic options to suit diverse preferences and plumbing configurations.

This article provides a comprehensive overview of soap dispenser pumps for sinks, exploring their types, materials, installation, maintenance, and factors to consider when selecting the optimal pump for a specific application. Understanding these aspects enables informed decision-making when choosing a soap dispenser pump that balances functionality, durability, and aesthetic appeal.

Types of Soap Dispenser Pumps

Soap dispenser pumps for sinks can be categorized based on their mechanism of operation and installation method. The most common types include manual pumps, automatic (touchless) pumps, and integrated sink systems. Each type possesses distinct advantages and disadvantages regarding ease of use, hygiene, and installation complexity.

Manual Pumps: These are the most prevalent type of soap dispenser pump. They operate through a simple mechanical action, typically involving pressing down on a pump head. This action draws soap from a reservoir through a tube and dispenses it through an outlet. Manual pumps are generally more affordable and easier to install compared to automatic options. They rely on user contact to dispense soap, which can be a concern in environments where minimizing germ transmission is crucial.

Manual pumps can be further classified by their material (plastic, stainless steel, brass, etc.) and design. Plastic pumps are lightweight and cost-effective, while stainless steel and brass pumps offer greater durability and a more premium aesthetic. The design can range from sleek and modern to traditional and ornate, allowing for integration with various sink and countertop styles.

Automatic (Touchless) Pumps: Automatic soap dispenser pumps utilize infrared sensors to detect the presence of hands and automatically dispense a pre-determined amount of soap. This hands-free operation promotes hygiene by minimizing contact with the dispenser, reducing the spread of germs. These pumps are battery-operated or electrically powered, requiring a power source near the sink.

Automatic pumps offer adjustable dispensing volumes and sensor sensitivity settings, allowing users to customize the amount of soap dispensed and prevent accidental activation. However, they are generally more expensive and require more complex installation than manual pumps. Maintenance may also involve replacing batteries or ensuring a consistent power supply.

Integrated Sink Systems: Some sinks are designed with integrated soap dispenser systems. These systems are built directly into the sink structure, often featuring a dedicated soap reservoir and pump mechanism hidden beneath the sink. Integrated systems provide a seamless and aesthetically pleasing solution but typically require professional installation and may be more difficult to repair or replace than standalone pumps.

Integrated systems can be either manual or automatic. The choice often depends on the overall design and functionality of the sink. These systems are commonly found in high-end residential and commercial settings, where aesthetics and ease of maintenance are paramount.

Materials and Construction of Soap Dispenser Pumps

The materials used in the construction of a soap dispenser pump significantly impact its durability, resistance to corrosion, and aesthetic appeal. Various materials are employed, each with its own set of advantages and disadvantages. Common materials include plastic, stainless steel, brass, and ceramic.

Plastic: Plastic is a cost-effective material widely used in soap dispenser pumps. It is lightweight, resistant to many chemicals, and can be molded into various shapes and colors. However, plastic is more susceptible to wear and tear than metal alternatives and may degrade over time, especially with exposure to harsh chemicals or UV light. Plastic pumps are often found in budget-friendly options and are suitable for light to moderate use.

Different types of plastic are used, including ABS (Acrylonitrile Butadiene Styrene) and polypropylene. ABS offers good impact resistance and durability, while polypropylene is known for its chemical resistance. The choice of plastic depends on the specific requirements of the application.

Stainless Steel: Stainless steel is a popular choice for soap dispenser pumps due to its durability, corrosion resistance, and sleek aesthetic. It is resistant to rust and staining, making it ideal for use in wet environments like kitchens and bathrooms. Stainless steel pumps are generally more expensive than plastic pumps but offer a longer lifespan and a more premium appearance. They are also easy to clean and maintain.

Different grades of stainless steel are available, with 304 and 316 being the most common. Grade 304 offers good corrosion resistance for general applications, while grade 316 contains molybdenum, which enhances its resistance to chlorides and makes it suitable for harsher environments such as coastal areas.

Brass: Brass is another durable and corrosion-resistant material often used in soap dispenser pumps. It offers a classic and elegant aesthetic and is resistant to bacterial growth. Brass pumps are typically more expensive than stainless steel pumps but provide a timeless look and exceptional durability. They may require polishing to maintain their shine and prevent tarnishing.

Brass alloys vary in composition, with some containing lead. It's important to choose lead-free brass for soap dispenser pumps to ensure water safety and compliance with regulatory standards.

Ceramic: Ceramic is sometimes used for the pump head or reservoir of soap dispensers. It offers a decorative and durable option that is resistant to staining and scratching. Ceramic pumps can add a touch of elegance to a bathroom or kitchen but are more fragile than metal alternatives and may be susceptible to breakage if dropped or subjected to impact.

Ceramic components are often combined with other materials such as stainless steel or plastic to provide structural support and enhance functionality. The aesthetic appeal of ceramic makes it a popular choice for decorative soap dispensers.

Installation and Maintenance of Soap Dispenser Pumps

Proper installation and regular maintenance are essential for ensuring the reliable operation and longevity of a soap dispenser pump. The installation process varies depending on the type of pump and the sink configuration. Maintenance typically involves cleaning the pump mechanism and reservoir to prevent clogs and bacterial growth.

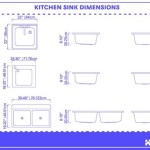

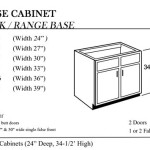

Installation Procedures: The installation of a soap dispenser pump generally involves drilling a hole in the sink or countertop, inserting the pump through the hole, and securing it in place with a nut or clamp. The reservoir is then connected to the pump via a tube. Step-by-step instructions are usually provided with the pump, and it's important to follow these instructions carefully to ensure proper installation.

For manual pumps, the installation process is relatively straightforward and can typically be completed by a homeowner with basic plumbing skills. Automatic pumps may require electrical connections, which may necessitate professional installation. Integrated sink systems require more complex installation procedures and are best handled by a qualified plumber.

Troubleshooting Common Issues: Common issues with soap dispenser pumps include clogs, leaks, and dispensing problems. Clogs can occur when soap or other debris accumulates in the pump mechanism or tube. Leaks may result from loose connections or damaged seals. Dispensing problems can be caused by airlocks, low soap levels, or a malfunctioning pump mechanism.

Troubleshooting often involves disassembling the pump, cleaning the components, and reassembling it. Checking for loose connections and replacing worn-out seals can also resolve leaks. Ensuring that the soap reservoir is adequately filled and that there are no airlocks in the system can address dispensing problems.

Cleaning and Maintenance: Regular cleaning is crucial for preventing clogs and maintaining hygiene. The soap dispenser pump and reservoir should be cleaned periodically with warm water and mild soap. Vinegar or diluted bleach can be used to disinfect the pump and kill bacteria. It's important to rinse the pump thoroughly after cleaning to remove any residue.

For automatic pumps, the sensor area should be cleaned regularly with a soft cloth to ensure accurate detection. Battery replacement may also be necessary for battery-operated models. Regularly inspecting the pump for signs of wear and tear and addressing any issues promptly can extend its lifespan and prevent costly repairs.

Factors Affecting Longevity: Several factors can influence the longevity of a soap dispenser pump. The quality of materials, the frequency of use, the type of soap used, and the level of maintenance all play a role. Choosing a pump made from durable materials like stainless steel or brass, using mild soaps, and performing regular cleaning and maintenance can significantly prolong its lifespan.

Exposure to harsh chemicals, excessive force, and improper installation can all shorten the lifespan of a soap dispenser pump. By addressing these factors, users can ensure that their soap dispenser pump provides reliable service for many years.

Plumbflex Kitchen Sink Stainless Steel Soap Dispenser Built In Design For Counter Top With Large Liquid Bottle Brushed Nickel

Proox Built In Sink Soap Dispenser Or Lotion For Kitchen Brushed Nickel Abs Pump Head Pr I803 Bn The Home

Casabella Sink Sider Solo With Sponge Chrome Plating Black

Kitchen Sink Soap Dispenser Extension Tube Kit Stainless Steel Countertop Pump

Eeekit Kitchen Sink Soap Dispenser 300ml Built In For Sturdy Modern Brushed Nickel Countertop Hand

Plumbflex Kitchen Sink Stainless Steel Soap Dispenser Built In Design For Counter Top With Large Liquid Bottle Brushed Nickel 1000e

Soap Dispenser Pump For Kitchen Sink W Extension Tube Kit Liquid

Kitchen Sink Soap Dispenser Pump Solid Stainless Steel 17 Ounce So

Culp Deck Mounted Kitchen Sink Soap Dispenser 400ml 13 5oz Pump Brass Construction

Stainless Steel Sink Soap Dispenser Extension Tube Kit For Kitchen Hand Pumps Detergent Liquid Lotion New Silver