Navigating the Market for Used Commercial Stainless Steel Sinks With Drainboards

The commercial kitchen, a hub of activity and productivity, demands equipment that can withstand rigorous use while maintaining hygiene standards. Stainless steel sinks, particularly those featuring integrated drainboards, are indispensable components in such environments. These sinks facilitate efficient washing, rinsing, and sanitizing of dishes, utensils, and food preparation surfaces. Opting for used commercial stainless steel sinks with drainboards presents a cost-effective alternative to purchasing new equipment, allowing businesses to allocate resources to other crucial areas. However, a thorough understanding of the market, condition assessment, and specific requirements is essential for making informed purchasing decisions.

Commercial stainless steel sinks with drainboards are designed to handle large volumes and frequent use. Their durable construction ensures longevity, while the stainless steel material offers resistance to corrosion, stains, and bacterial growth. The integrated drainboard provides a convenient space for items to air dry after washing, preventing water accumulation and promoting efficient workflow. These sinks are commonly found in restaurants, catering services, bakeries, hospitals, and other food service establishments.

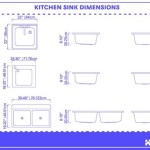

The used equipment market offers a variety of options, ranging from single-compartment sinks with single drainboards to multi-compartment sinks with drainboards on either side. The selection process should involve a careful evaluation of the sink's dimensions, compartment configuration, drainboard size, and overall condition, ensuring that the chosen sink meets the specific needs of the kitchen operation.

Key Considerations Before Purchasing a Used Sink

Before committing to a purchase, there are several critical factors to consider when evaluating used commercial stainless steel sinks with drainboards. These factors can significantly impact the sink's performance, lifespan, and suitability for the intended application. A proactive approach to assessing these elements minimizes the risk of acquiring substandard equipment and maximizes the return on investment.

Firstly, a thorough inspection of the sink's structure, including the basin, drainboard, legs, and plumbing connections, is paramount. Look for signs of extensive damage, such as deep scratches, dents, or corrosion. While minor cosmetic imperfections may be acceptable, structural damage can compromise the sink's integrity and shorten its lifespan. Pay particular attention to welded joints, as these areas are susceptible to stress and potential failure. Any evidence of prior repairs should be scrutinized, and the quality of the workmanship should be assessed. If rust or corrosion is present, the extent of the damage should be carefully evaluated to determine whether it is superficial or has penetrated deeper into the metal.

Secondly, verifying the gauge and grade of the stainless steel is essential. Lower-grade stainless steel is more prone to corrosion and staining, while thinner gauges may lack the necessary strength to withstand heavy use. Ideally, the sink should be constructed from 304 stainless steel, a durable and corrosion-resistant alloy commonly used in commercial kitchens. The gauge of the stainless steel should be sufficient to support the weight of the items being washed and rinsed. A thicker gauge indicates greater durability and resistance to deformation. Inquiring about the sink's original specifications and comparing them to its current condition can provide valuable insights into its overall quality.

Finally, evaluating the drainboard's integrity is important. The drainboard should be free from cracks, chips, or significant warping, which could impede water drainage and create unsanitary conditions. The drainboard's slope should be sufficient to allow water to flow freely into the sink basin. Inspect the drainboard's surface for any signs of staining or discoloration that may indicate previous misuse or inadequate cleaning. Consider the drainboard's size and configuration in relation to the type and volume of items that will be placed on it. A drainboard that is too small or awkwardly shaped may hinder efficiency and create bottlenecks in the workflow.

Assessing the Sink's Condition and Functionality

Beyond a visual inspection, assessing the sink's condition and functionality requires a more hands-on approach. Evaluating the plumbing connections, drainage system, and overall stability ensures that the sink operates efficiently and reliably. Any deficiencies in these areas can lead to operational problems and necessitate costly repairs.

The plumbing connections should be inspected for leaks, corrosion, or damage. Check the condition of the faucets, sprayers, and other plumbing fixtures. Ensure that all connections are secure and properly sealed. Replace any worn or damaged components before installing the sink to prevent water leaks and potential water damage. Test the water pressure and flow rate to ensure that the sink provides an adequate water supply for washing and rinsing. Inspect the drainpipes for clogs or obstructions that could impede drainage. Consider replacing old or corroded drainpipes to improve drainage efficiency and prevent future plumbing problems.

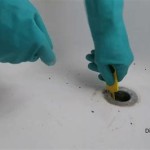

The drainage system should be tested to ensure that water drains quickly and efficiently from both the sink basin and the drainboard. A slow or clogged drain can create unsanitary conditions and hinder workflow. Inspect the drain strainer and trap for debris, and clean them thoroughly. Check the drainpipe for any kinks or bends that could restrict water flow. If the drainage is slow or erratic, consider using a drain cleaner or contacting a plumber to address the issue. Ensure that the drainpipe is properly connected to the plumbing system to prevent leaks and sewage backups.

The sink's overall stability should be assessed to ensure that it is securely mounted and does not wobble or shake during use. Check the condition of the legs or mounting brackets, and ensure that they are securely attached to the sink and the floor. If the sink is equipped with adjustable feet, ensure that they are properly leveled to prevent wobbling. A stable and secure sink is essential for safety and efficiency. Reinforce or replace any damaged or unstable legs or mounting brackets to ensure the sink's structural integrity.

Understanding Different Types and Configurations

Commercial stainless steel sinks with drainboards are available in a variety of types and configurations to suit different kitchen layouts and operational needs. Understanding the various options available can help businesses select the most appropriate sink for their specific requirements. Factors such as the number of compartments, drainboard placement, and overall size should be considered in relation to the intended use and available space.

Single-compartment sinks with a single drainboard are suitable for smaller kitchens or applications where washing and rinsing are performed separately. These sinks typically have a single large basin and a drainboard on one side, providing ample space for washing and air-drying dishes and utensils. They are often used in cafes, bars, and small restaurants where space is limited. The drainboard can be positioned on either the left or right side, depending on the kitchen layout and workflow.

Double-compartment sinks with drainboards are ideal for kitchens that require separate washing and rinsing stations. These sinks have two basins, allowing for efficient separation of tasks. A drainboard is typically located on one or both sides of the sink, providing ample space for air-drying washed items. Double-compartment sinks are commonly used in restaurants, catering services, and other food service establishments where higher volumes of dishes and utensils are processed.

Three-compartment sinks with drainboards are designed for kitchens that adhere to the traditional three-sink method of washing, rinsing, and sanitizing. These sinks have three separate basins, each designated for a specific task. A drainboard is typically located on either side of the sink, providing ample space for air-drying sanitized items. Three-compartment sinks are required in many jurisdictions to comply with health and safety regulations. They are commonly used in restaurants, cafeterias, and other food service establishments that handle large volumes of dishes and utensils.

Beyond the number of compartments, the configuration of the drainboards can also vary. Some sinks have drainboards on both sides, while others have a single drainboard on one side. The placement of the drainboard should be considered in relation to the kitchen layout and workflow. Additionally, the size and slope of the drainboard can impact its efficiency. A larger drainboard can accommodate more items, while a steeper slope promotes faster drainage.

The size of the sink itself is also an important consideration. The sink should be large enough to accommodate the items being washed, but not so large that it is cumbersome or takes up too much space. The depth of the sink basin should also be considered. A deeper basin can accommodate larger items, but may also require more water and effort to fill and empty.

Other factors to consider include the material of the sink, the type of faucet, and the presence of any accessories, such as sprayers or pre-rinse units. The sink should be constructed from durable and corrosion-resistant materials, such as 304 stainless steel. The faucet should be easy to operate and provide an adequate water flow rate. Sprayers and pre-rinse units can be helpful for removing food debris from dishes before washing.

Before making a purchase, it is important to carefully consider the specific needs of the kitchen operation and select a sink that meets those needs. Consulting with a kitchen equipment specialist can be helpful in determining the best type and configuration of sink for a particular application. It is also important to factor in the cost of installation and any necessary plumbing modifications.

Used Stainless Steel Drop In Sink

Hobart 3 Compartment Sink With 2 Drainboards Used

Stainless Steel Kitchen Sink Utility Prep W Faucet Drainboard

72 Inch Stainless Steel Two Compartment Sink With 2 Drainboards And Faucet New

Universal Lj1818 2rl 72 Two Compartment Sink W Drainboards

Freestanding Kitchen Sink Stainless Steel Single Bowl W 2 Drainboards

Regency 54 16 Gauge Stainless Steel One Compartment Sink With 2 Drainboards 18 X 14 Bowl

Kitchen Used Stainless Steel Washing Sinks Durable Water Sink With Drainboard Basin And

Phoenix Heavy Duty 16 Gauge Stainless Steel Sinks With Drainboard Va

Joe Replaces A Vintage Porcelain Drainboard Kitchen Sink With New Elkay Stainless Steel Retro Renovation